CASE

STUDY

- Home /

- Case study /

- Kineco Kaman Composites India Private Limited

Optimizing Design to Manufacturing Process of Composite Aerospace Parts and Assemblies

Composite DesignSimulation Kineco Kaman Composites India Private Limited

Overview

Kineco Kaman Composites India (KKCI) is a multinational joint venture between Kaman Aerospace Group (USA) and Kineco Limited (India). It manufactures advanced composite structural parts and assemblies for aerospace and defence applications using carbon, aramid and glass fiber with various core materials and autoclave curing technology.

The Manufacturing Engineering and Tooling departments at Kineco Kaman are responsible for the detailing of composite parts and assemblies and designing of their corresponding tools. This is based on detailed requirement-specifications provided by their customers.

Challenges

Kineco Kaman was keen to optimize its design-to-manufacturing process for composite structural aerospace parts and assemblies. Some of the challenges faced by the team for composite product design and manufacturing were:

- Longer cycle-time with multiple development iterations for design to manufacturing of composites

- Constant pressure to reduce time and associated cost while minimising the user’s ramp-up time for manufacturing of complex composite products

- The design is highly dependent on manufacturing constraints. This makes it necessary to define and analyse these constraints as per the parameters and specs early on in the design process, and synchronize manufacturing studies with design evolutions.

- Ensure manufacturability and quality of composite aerospace structural parts and assemblies

- Simplify the time-consuming process of troubleshooting composite layup on the shop floor by providing detailed manufacturing documentation while avoiding data translation concerns

Further, the aerospace and defence sector demands a high degree of accuracy in design and tooling. Therefore, it is key that parts designed by Kineco Kaman are completely compatible with the customer data.

In order to have seamless data collaboration with their customers and to have effective design reviews, they needed a robust 3D modelling tool for generation of composite design of parts.

The CATIA Composite and Mechanical Design Solutions helped in addressing these challenges.

Products Used

Kineco Kaman invested and started using CATIA - Composites Design 3 (CD3), an advanced composites process centric solution that allows manufacturers to reduce the time needed to design and manufacture composites parts. The all-in-one solution for composite part design provides a productive process oriented environment dedicated to preliminary design, engineering detailed design, and manufacturing detailed design.

In addition, they also started using the CATIA Mechanical Design Solution and the 3D Functional, Tolerancing, and Annotation product to develop tooling in parallel to the preliminary design and engineering detailed design phase of composite parts.

Approach

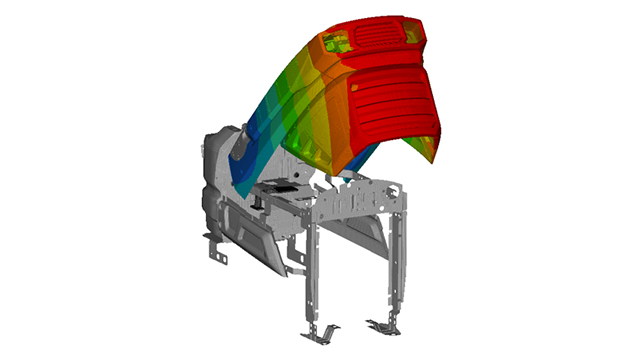

Leveraging the CATIA Composites Design software, Kineco Kaman was able to create a composite digital mock-up model taking into account all the relevant engineering and manufacturing constraints. This not only helps in achieving accurate shop floor documentations and flat pattern ply geometry for ply cutting applications, but also assists in the creation of the mold geometry for machining applications.

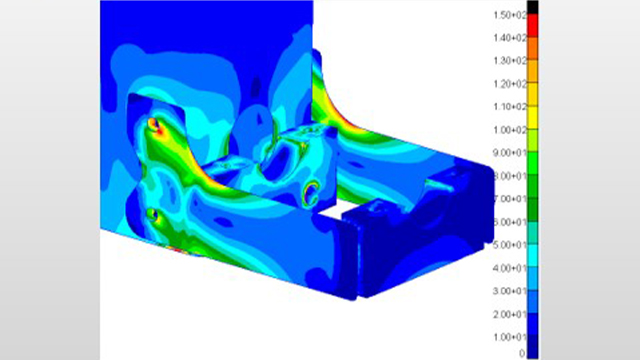

The team can also perform draping simulation for complex geometries to identify dart location and fiber orientation changes prior to the manual layup.

The software enables the team to share its intuitive 3D models with clients in neutral formats with embedded manufacturing constraints such as tolerances and dimension. The implementation of the CATIA Design Solution suitably helped and supported production activities where tooling was required. It also helped Kineco Kaman ensure zero loss of data since the team could view data on the same platform as sent by their customer.

The SOLIZE team worked closely with the Kineco Kaman team through the entire implementation right from sharing demos and trial licenses to providing comprehensive training and sharing relevant use cases.

Benefits

- Working with the same environment as that of the customer has helped eliminate translational errors and data loss.

- Design right first time achieved by taking into account manufacturing constraints early in the design phase. Reduced initial design time by 30% and design modification cycle time by 40%.

- Manufacturing documentation creation is efficiently produced for the down-stream applications. Enabled cutting of manufacturing design time in half.

- Modifications can be made directly onto the CAD file, eliminating the need to create multiple physical templates.

- Significant time savings in the overall process since fewer iterations are required to be done at the shop floor level.

- State of the art mechanical designing capabilities enabling Kineco Kaman to go from build to print to design of products.

“The CATIA - Composites Design 3 (CD3) solution implementation has helped us significantly elevate our offering, and put us in the same league as the big international players in the industry. We would like to acknowledge SOLIZE India’s constant support in helping us utilise the software and understand its benefits, offering comprehensive training and being there to address any issues quickly and effectively.”

- Adarsh Roy

Dy. Manager - Engineering, Kineco Kaman Composites India Pvt. Ltd.