XR

- Home /

- Service / Solution /

- XR

Tying together planning, design, manufacturing, and sales

“XR”—creating and communicating the strengths of our customer’s products

In the manufacturing field, XR (i.e., VR, AR, and MR) is many used in “training for manufacturing, maintenance, and inspections” and “design and prototyping simulations.” This creates benefits such as increasing the efficiency with which work skills are acquired and reducing lead times and costs by enabling product verification before the actual product is manufactured.

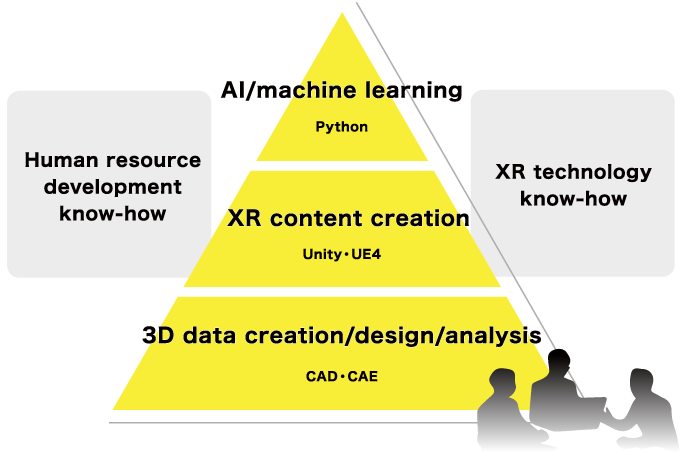

SOLIZE contributes to improving customer’s manufacturing by combining existing digital technology or 3D data utilization technology with XR. We also are working on developing new talent by combining our knowhow of developing engineering talent over 30 years.

SOLIZE’s XR service for manufacturing

XR (extended reality) is an umbrella term for advanced technologies such as AR (augmented reality), VR (virtual reality), and MR (mixed reality). SOLIZE provides services that increase the value of engineering and products based on our definition of XR as “communication tools that strongly link people, objects, and things.”

Examples of things made possible with XR

- Create new value by linking existing technologies with new technologies

- Promote communication between the producer and users, between companies, between departments, and between experienced and inexperienced personnel to provide better products efficiently

-

Dispatching engineers

SOLIZE dispatches development engineers with CAD skills and Unity development skills.

Details here -

Production of content

SOLIZE’s development engineers with extensive experience handling 3D data produce “content for discussing UI and UX” and “VR space and data” for customers.

Details here -

Training for engineers

SOLIZE’s training development staff with extensive knowledge of 3D tools create training curriculums for customers.

Details here

Engineer dispatching

Characteristics

- Can start immediately on the field at a small scale without needing to prepare for outsourcing

- Can introduce tools affordably compared to introducing high-end CADs

We solve the following kinds of problems:

- Can’t check UI until the mockup is complete

- Digital development only results in quantification or comparison of numbers, and is not creating product value

- Creating content for VR is expensive (want to create VR content and test its effectiveness casually)

- Equipment for VR, which was a large investment, are not being used (the equipment is there, but there is a shortage of engineers who can use it)

Reference case studies

-

Check the ease of assembly of parts and workflow, train intuitively with VR -

Feed back VR operation records into CAD -

Overlay the 3D model over the analysis results

Commissioned production of content

Characteristics

- Developed by engineers with extensive experience handling 3D data

- Wealth of experience in combining XR with other devices to develop technologies

We solve the following kinds of problems:

- Considering introducing VR but cannot develop content in-house

- Can’t figure out what kind of PoC or content to create

Reference case studies

-

Creation of a customized virtual space -

Creation of 3D models using a highly accurate 3D scanner

Training for engineers

Characteristics

- Wealth of engineer development knowhow gathered over 30 years

- SOLIZE training development personnel who are well-versed in the use of 3D tools in manufacturing will be in charge

We solve the following kinds of problems:

- Have received training in the past but has not been able to implement it in work

- Want to learn VR technology but don’t know what to learn

- Has no environment or resources to implement training internally

Reference case studies

CAD

・Offers unique training materials for CATIA, NX, Creo

・Has material for training designers, which encompass diagrams and analysis, in addition to modeling

Unity・UE4

・Creation of content on ways to use XR specific to the development site

・Creation of original content

※Can also be combined with training materials for CAE , MBD, and others

Characteristics of SOLIZE engineers

SOLIZE Corporation has been supporting the manufacturing industry with digital engineering technologies such as 3D CAD and 3D printers, based on its philosophy of “True evolution you can experience”. Since its founding in 1990, SOLIZE has trained more than 1,000 engineers while providing engineering services.

- Understands the manufacturing process from design to development backed by experience of having implemented internal training for engineers and manufactured products

- Wealth of knowledge and experience in 3D CAD

- Has both the skills to produce VR content and the programming skills, and can propose ways to utilize VR technology in product development