3D printing prototypes

- Home /

- Service / Solution /

- 3D printing prototypes

Supporting our customers in development and prototyping, using all methods including 3D printers

SOLIZE provides a comprehensive service from developing specifications to data creation, to manufacturing, to secondary processing, and inspection.

We offer a wide range of services to accommodate deadlines and budgets, including not only 3D printing but also cutting, sheet metal processing, casting, molding, and injection molding.

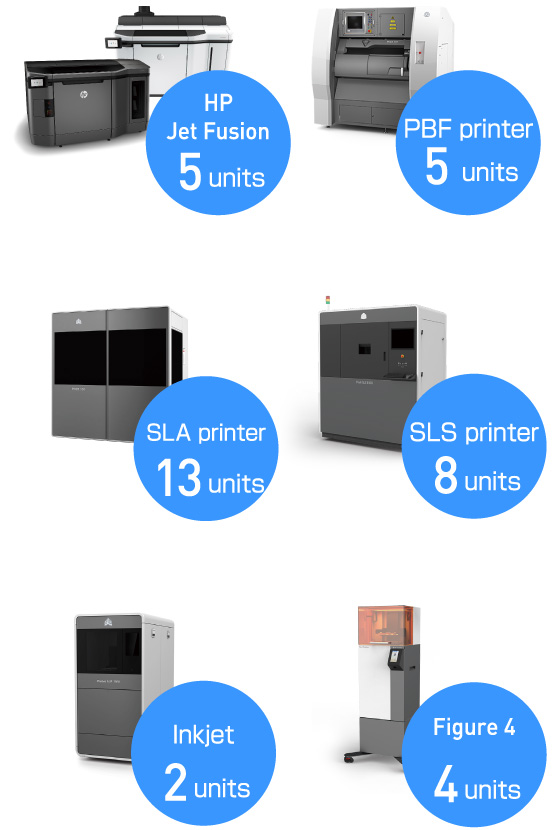

With one of the largest fleets of 3D printer in Japan (over 41 units), we can respond to customer needs with short delivery times.

In addition, we can produce not only mock-ups, but also high-heat-resistant parts and parts for performance evaluation tests, using a diverse range of materials, including three types of materials developed by SOLIZE.

SOLIZE supports our customers' development and prototyping with 3D printed prototypes which we have supplied as final product parts to automobile manufacturers that require high quality.

Characteristics of SOLIZE’s 3D printed prototypes

-

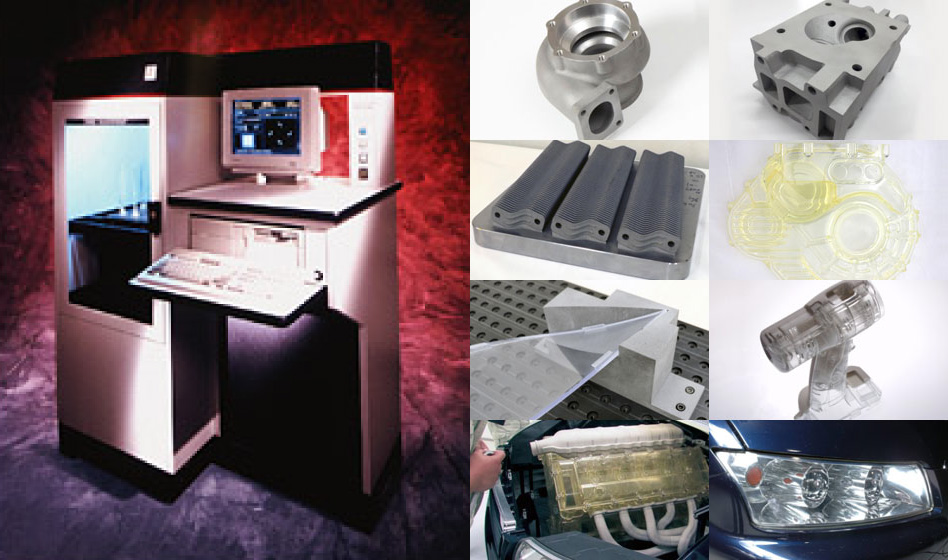

Track record of using 3D printers for over 30 years

SOLIZE was the first 3D printing service bureau in Japan to introduce 3D printers, and have been working in the field of additive manufacturing for over 30 years. We have served over 2,000 customers, including domestic automotive manufacturers.

-

Largest fleets of high-end 3D printers in Japan

We have high-quality, high-precision, high-end 3D printers from 3D Systems and HP. We use the printer best suited for the application and can also recommend printers to maximize QCD for our customers. We manufacture more than 80,000 parts per year.

-

Technical capabilities and development capabilities to make full use of 3D printers

We also perform design for additive manufacturing (DfAM) and material development. We can produce designs for mass production using a 3D printer and develop manufacturing conditions for new materials.

Details here

-

In-house plants and sales offices that put customers’ minds at ease

We do our 3D printing in-house: plastics are 3D printed at our Yamato Plant or Toyota Plant and metals at our Yokohama Plant. As a result, we are able to provide thorough quality control and flexible support that meets the needs of our customers. We have four sales offices in Japan that support our customers to their desired outcomes.

-

Can also provide inserts, painting, assembly, and other secondary processing

SOLIZE contributes to the improvement of our customers' development process. We add value by taking on projects as a whole and reducing costs, manufacturing and procuring not only the parts that the customer asked to be manufactured, but also the surrounding parts, assembling them, and delivering them as a unit.

-

Supporting all manufacturing, including methods other than 3D printing

Depending on the part to be produced and its intended use, we also use methods other than 3D printing. We ask for our customer's intended use and quantity of the parts, as well as the desired delivery date to propose plans that maximize QCD for our customers.

Services

3D data creation

We create designs and 3D data that are suitable for our customer's intended use based on their final objective. Design for additive manufacturing will be used for customers thinking of creating a final product using 3D printing. We can also optimize topology optimization to reduce weight and other purposes.

-

Design

We handle a wide range of fields, from automotive parts to home appliances, consumer goods, and toys. We can also create design surfaces from hand-drawn sketches and 2D design drawings, and ultimately provide design data suitable for 3D printer output.

-

Modeling

A group of CAD engineers well-versed in manufacturing, including the characteristics of 3D printers and secondary processing, handle a wide range of tasks from modeling based on 2D drawings and rough sketches, to suggesting dividing, integration, and other manufacturing methods, adjusting dimensions to suit secondary processing, adding processing allowances, and creating inspection drawings.

-

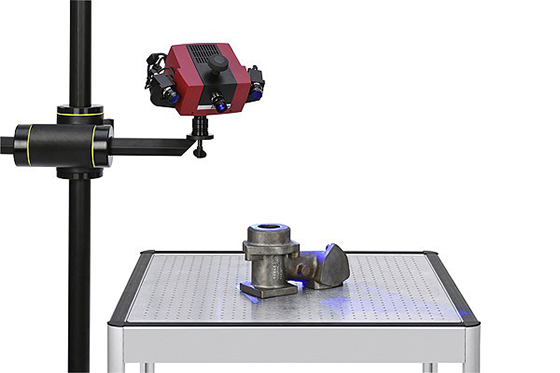

Reverse engineering

Using a high-precision 3D scanner, we can take point cloud measurements of the object in question and convert them into 3D data. Based on this, we can alter its shape and dimensions in CAD for analysis and comparison, or create a prototype and conduct comparison experiments with the product in question.

-

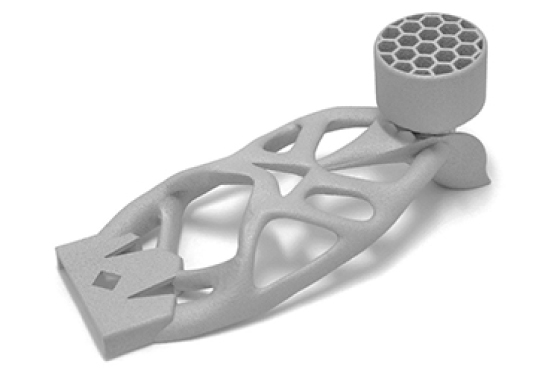

Design for additive manufacturing (DfAM)

We assist customers in strengthening their product capabilities by proposing ‘weight reduction’, ‘miniaturization’, ‘integration’ and ‘addition of functions’ that make use of the advantages of additive manufacturing. Compared to conventional manufacturing methods, additive manufacturing has the benefits of keeping initial investment costs low, reducing production processes, and reducing production lead times.

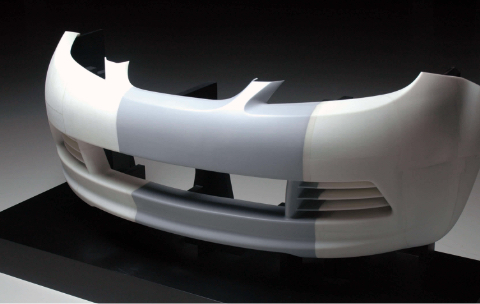

3D printing

SOLIZE, with one of the largest fleet of 3D printers in Japan, can make many different types of molds using 6 types of printers that use different techniques. We recommend the printer best suited to our customer’s needs. 3D printing can be used in a variety of situations, from creating prototypes to creating exhibition mock-ups, visualization models, lightweight models, and small-lot mass-produced products.

-

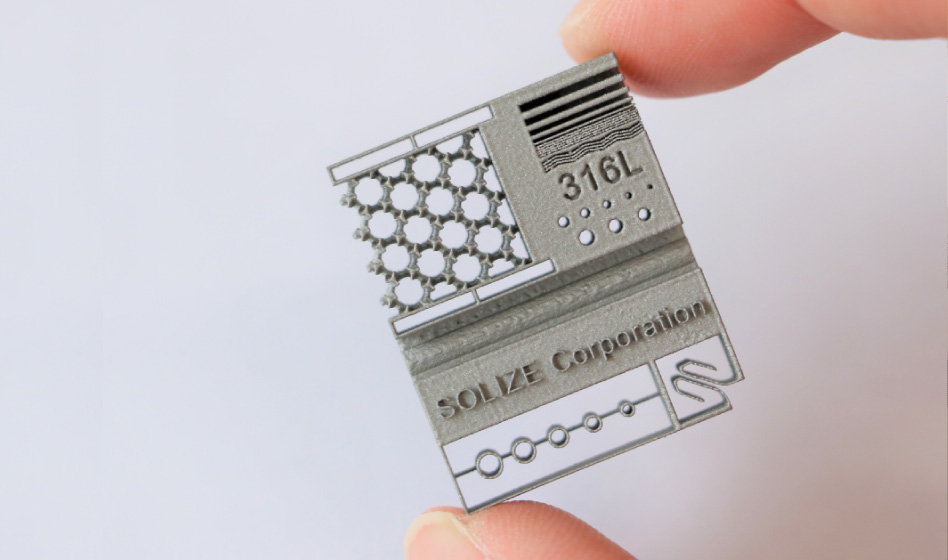

Powder bed fusion (PBF)

Compatible with materials such as steel, stainless steel, and aluminum alloys. This technique excels in reproducing surface roughness and fine shapes. It can also be used to create parts with complex hollow shapes that are difficult to manufacture using conventional processing methods.

-

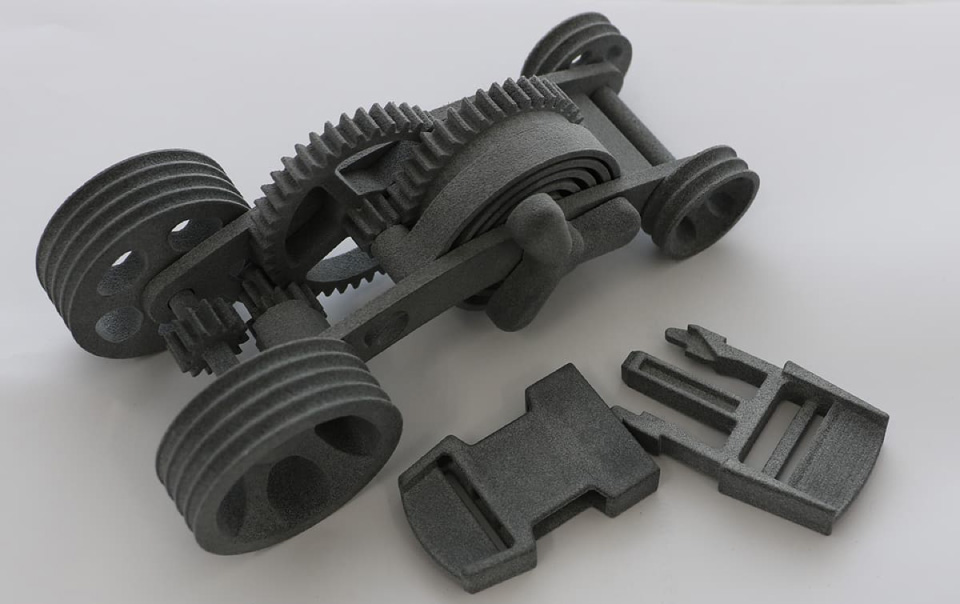

Selective laser sintering (SLS)

This technique uses thermoplastic material and has high strength. It can be used to make experimental models that can withstand various tests and is used to make objects for tests that require greater durability, such as wind tunnel tests and bench tests.

-

Multi-jet fusion(MJF)

With this technique, once the fusing agent is printed using an inkjet printer, it is heated using an infrared wavelength heater and melted via thermal reaction. Melting the agent surface by surface allows high speed production, making it suitable for final product manufacturing.

-

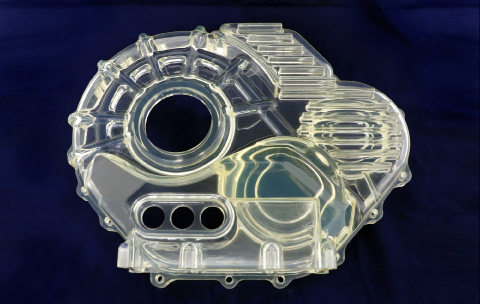

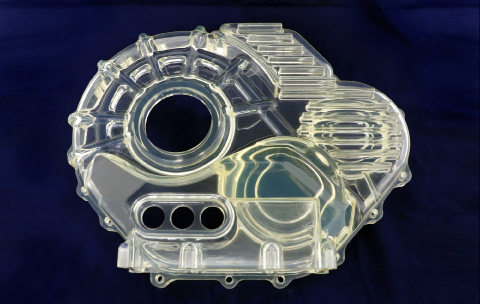

Stereolithography(SLA)

This technique can produce dimensions and surfaces with high accuracy. It is used to produce assembly confirmation models using tough materials to enable flow visualization using transparent plastics, to produce models using heat-resistant materials, as well as for vacuum casting and casting master models.

-

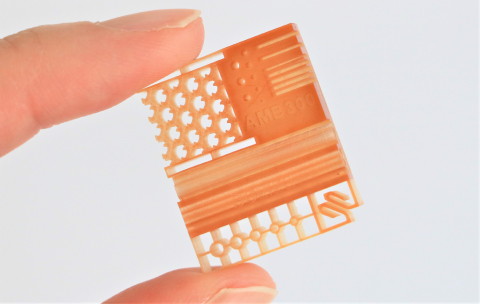

Digital light processing (DLP)

This technique can produce dimensions and surfaces with high accuracy, especially when reproducing intricate shapes and is suited for creating porotypes for connectors and similar objects. We offer a lineup of materials that can be used for functional testing, including heat-resistant materials that can withstand temperatures of 300℃ or more and flame-retardant materials that meet UL94-V0 standards. DLP is also suitable for high-speed modeling and small-lot mass production.

-

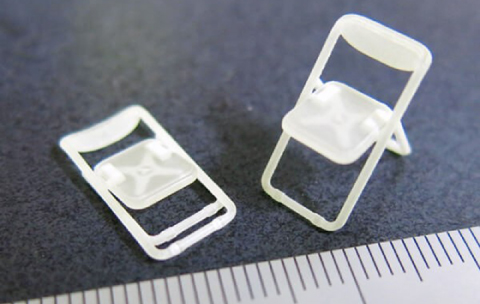

Inkjet

This printer uses inkjet technology and can be used to create intricate models. It cures acrylic materials using ultraviolet light. It excels at reproducing thin walls and fine holes, and can reproduce smooth surfaces and fine details.

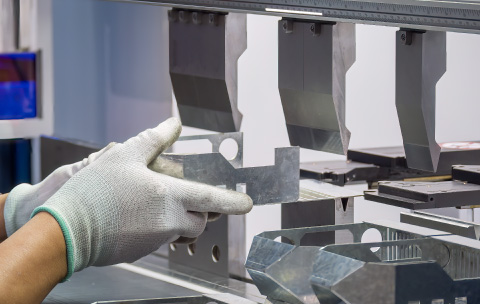

Other part manufacturing methods

SOLIZE’s prototyping service can also provide prototypes using a variety of methods other than 3D printing. We recommend the method best suited for the product’s intended use.

-

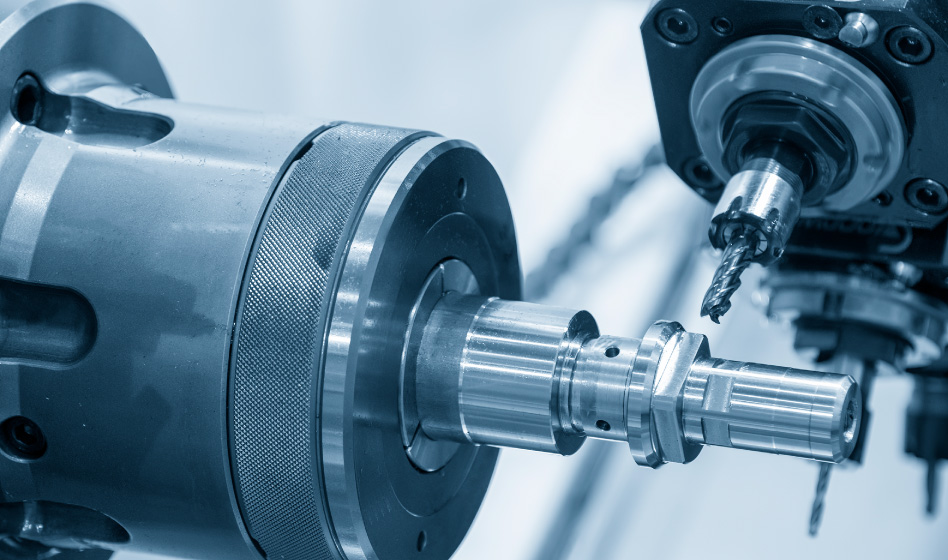

Cutting

We can cut a wide range of materials, from plastics (general plastics materials to super engineering plastic materials such as PEEK), as well as metals (aluminum, stainless steel, magnesium). We can also perform additional processing on the molded product to improve dimensional accuracy.

-

Sheet metal processing

We produce prototypes of brackets, cases, covers using sheet metal processing, starting from one unit up to tens of thousands of units. We also handle secondary processing such as plating, anodizing, assembly, and welding.

-

Casting

We provide castings with a short delivery time based on master models produced using 3D printers. In collaboration with casting prototype manufacturers, we support multiple casting methods, including plaster casting, lost foam casting, precision casting, and sand casting using sand molding.

-

Vacuum casting

We produce reverse molds made of silicone rubber using models produced using SLA or cut models as the master model. We can cast a wide range of materials, including ABS-like plastics, PP-like plastics, heat-resistant transparent materials, rubber, and UL-certified materials, and are also able to mix colors.

-

Prototype molding

This technique is suitable for small-lot mass production from prototypes to the final product. We can handle a wide range of plastics, from general thermoplastic resins to super engineering plastics. We can also handle undercuts and other complex shapes using slides and lifters.

Secondary processing after 3D printing

By applying secondary processing and finishing to parts created using a 3D printer, it is possible to achieve a look, texture, and performance comparable to the final product. By combining digital manufacturing with the craftsmanship of skilled workers, SOLIZE is able to achieve a high level of finish in a short turnaround time.

-

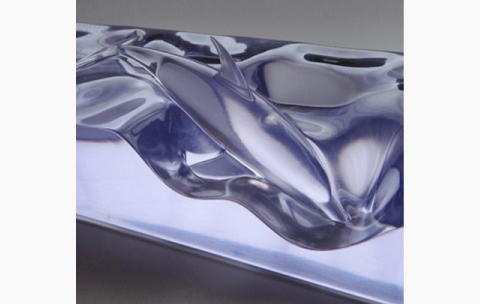

Finishing and polishing

Skilled workers finish the product to the optimum finish, from lightly removing the layered bumps to mirror finishing, depending on the intended use of the product.

-

Surface processing

We offer all kinds of surface processing methods, from various types of coating such as gloss and flocking, to printing, plating, aluminum evaporation, silvering, lamination, and sewing. We produce a wide range of products, from design mock-ups to show models for exhibitions.

-

Additional processing/dimension designation/assembly

High-precision prototypes can be created by machining the 3D printed parts that require dimensional accuracy and surface accuracy. Since only the necessary parts are machined, costs can be reduced and delivery times can be shortened at the same time. Assembly and fitting adjustments are also possible.

-

Inserts and anneal processing

We can also handle additional processing such as coloring, nutting, and press fitting of coils. In addition, annealing processes improve material properties and correct warping and deformation.

Inspection of 3D printed prototypes

We can meet all kinds of requests, from measuring the dimensions of the products to physical property testing including strength and heat resistance testing, as well as leak testing, depending on the customer's intended use.

-

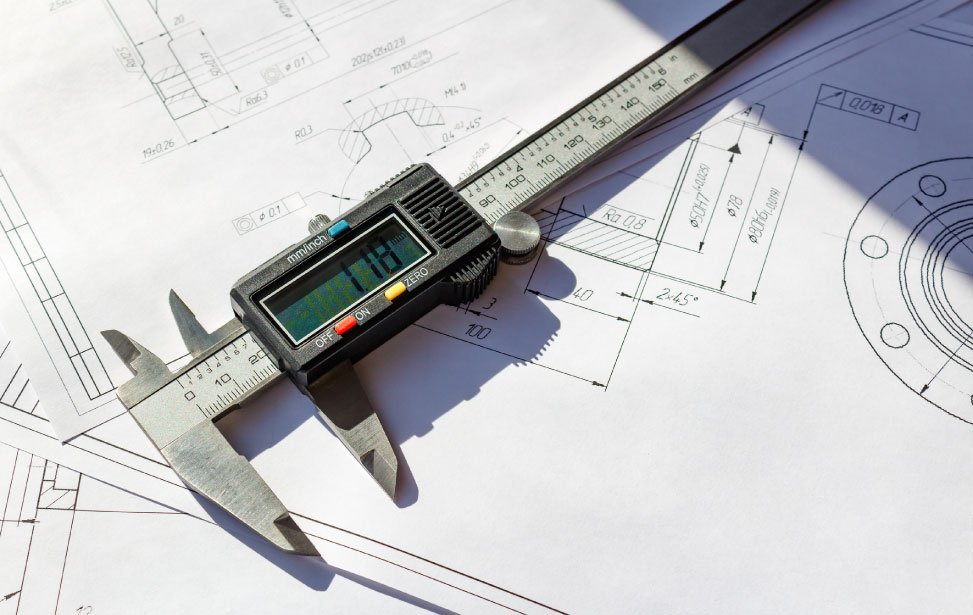

3D measurements

We have four non-contact and probe-contact 3D measuring machines. We can also perform dimensional inspections based on the tolerance specifications on the drawings, check relative positions from the criteria, and compare color maps of three-dimensional curved surfaces. In addition, we have a full range of standard measuring equipment, including calipers, micrometers, pin gauges, block gauges, and surface roughness meters, and we maintain quality stability by feeding back the results of our measurements into our processes.

-

Physical properties test

We also conduct material properties testing to meet advanced requirements such as strength and heat resistance. We reflect the results of the properties tests onto 3D data to suit the customer's testing requirements and environment, for example, conducting strength analysis and changing the wall thickness. Our engineers, who are well-versed in manufacturing, support the customer's product development by making the most of the potential of the prototype, by comparing it with mass-produced materials and checking its mechanical properties, such as heat and pressure resistance.

-

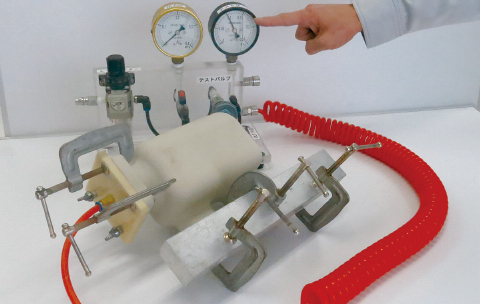

Leak tests

Leak tests are carried out on products that require airtightness and pressure resistance, such as engine intake parts and pressure vessel parts for automobiles. We check using compressed air and submerge the product to conduct visual checks for air bubbles. We comprehensively guarantee the pressure values required for performance evaluation, including the airtightness of the material itself and the sealability of the joints.

3D printers that SOLIZE owns

SOLIZE owns 42 high-end 3D printers (one of the largest fleets in Japan)

3D printing materials

With over 30 years of experience in providing 3D printing services in Japan, SOLIZE has more than 25 types of resin and metals in stock at all times to be able to meet our customers‘ needs with our wide range of materials. We also have a large selection of unique materials that we have developed over the years in response to our customers’ requests.

-

Transparent materials

Applicable technique: SLA/DLP

SL 7870, SIS-200, Tough Clear -

Highly heat-resistant materials

Applicable technique: SLA/DLP

Accura SL 5530, SIS-20, HI TEMP 300-AMB -

Tough material

Applicable technique: Selective laser sintering, Multi Jet Fusion

PA, PA12, etc.

-

Flame retardant materials

Applicable technique: DLP

High Temp 150℃ FR Black -

Rubber-like plastics

Applicable technique: Selective laser sintering, DLP

Flex, Figure 4 RUBBER-65A BLK -

Metals

Applicable technique: Powder bed fusion

Stainless steel, aluminum alloy, Inconel, maraging steel

| Printing technique | Materials that can be used |

|---|---|

| Stereolithography(SLA) | SIS-200, Accura Xtreme, SL 5510, SL 5530HT, SL 7800, SL 7810, SL 7870 |

| Digital light processing (DLP)/ Figure 4 | PRO-BLK10, Rigid White, RUBBER-65A BLK, HI TEMP 300-AMB, High Temp 150℃ FR Black, Tough Clear |

| Selective laser sintering (SLS) |

Nylon (DuraForm® PA), glass filled nylon (DuraForm® GF), powdered elastomer (DuraForm® FLEX), polypropylene, polystyrene |

| Multi jet fusion (MJF)) | PA12、PA12GB、PA11 |

| Inkjet | VisiJet Crystal |

| Powder bed fusion (PBF) | Maraging steel (1.2709), stainless steel (SUS316L), , Nickle alloy (Inconel 718), copper alloy (CuCr) |

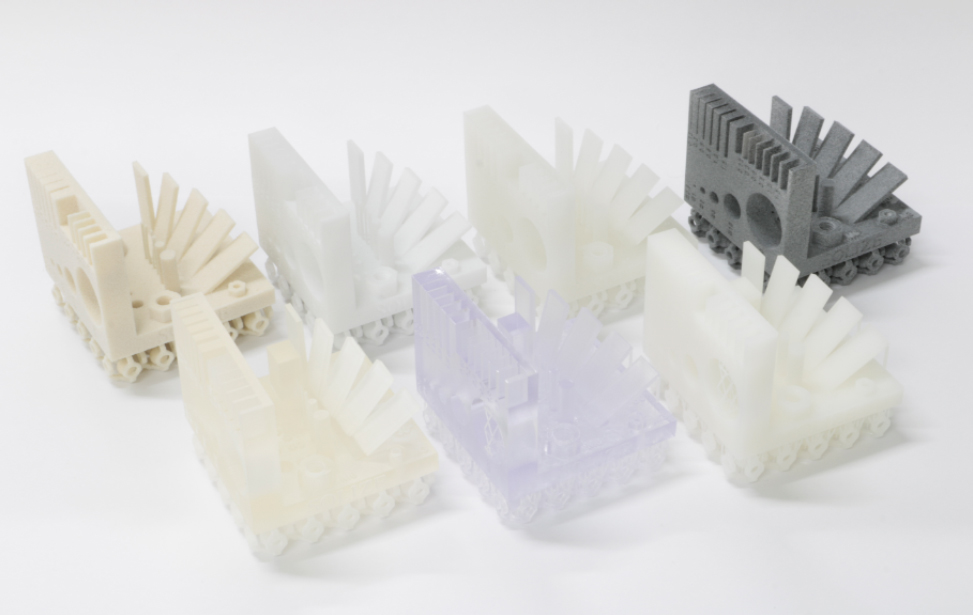

Case studies of models SOIZE have helped create

Here are some samples that SOIZE has created. We have a track record of creating models with short turnaround times and in small lots.

-

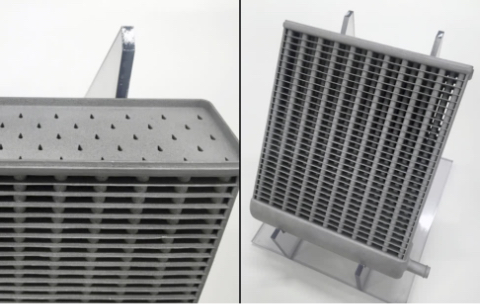

Heat exchanger

- Material: AlSi12

- Objective: Performance evaluation model

- Optimized design to create a shape that does not require internal supports.

- Integrated multiple parts to shorten turnaround time.

- Eliminated the need to braze pipes and fins.

- Created a teardrop-shaped cross-section to increase the surface area and improve the surface roughness of the internal flow channel.

-

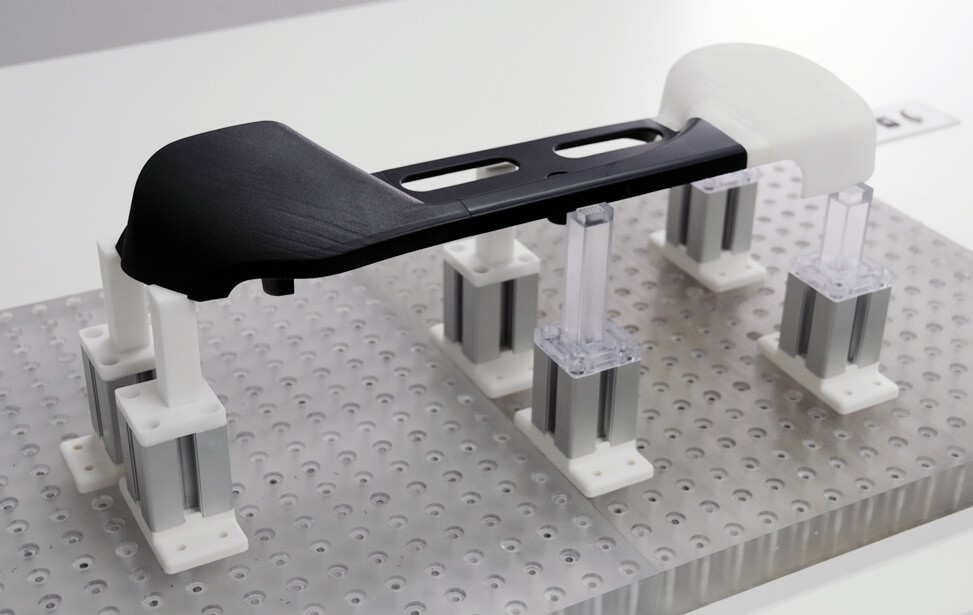

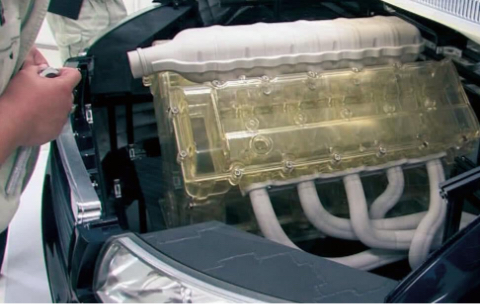

Engine assembly review model

- Material: Duraform® GF+heat-resistant resin

- Deadline: Around a week

- Secondary processing: Insert joining

Studying the engine assembly process in advance using a model made it possible to start up the production line early. In addition, the use of heat-resistant transparent materials made visualization tests possible.

-

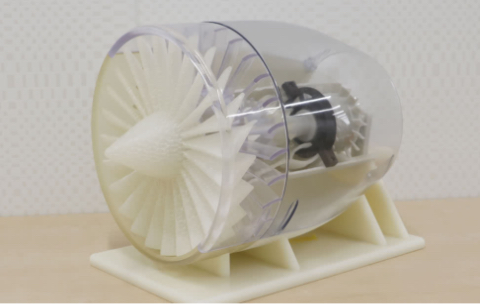

Jet engine

- Can combine 17 types of 3D printing techniques, including stereolithography and selective laser sintering, and 3D printing materials

- The largest lineup of materials in the industry

- Can deliver the product, with finishing, within a week

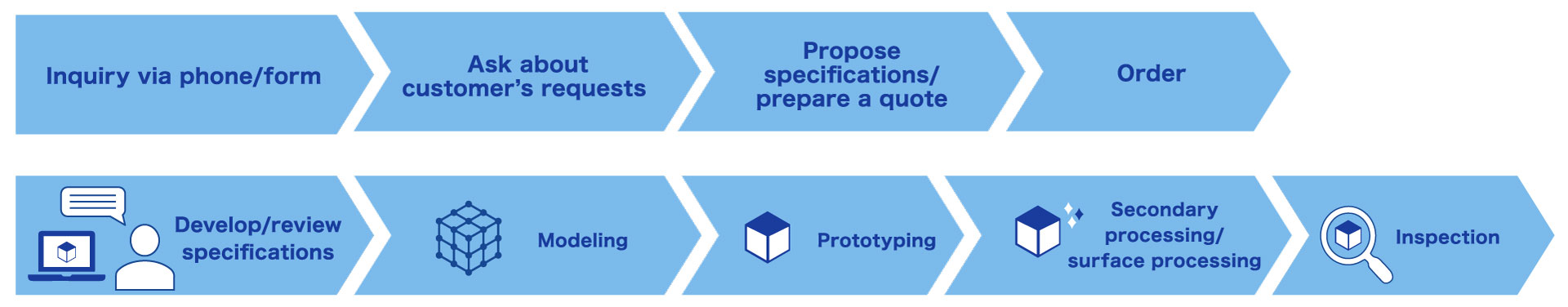

Flow of the 3D printed prototype manufacturing service

We first develop an accurate understanding of the intended use, and provide a comprehensive service from detailed specification review to data confirmation and pre- and post-processes tailored to the intended use.

We can create prototypes using not only 3D printing, but also casting, machining, sheet metal, prototype molds, plating, painting, aluminum deposition, and silvering. We offer a wide range of services to suit our customers' deadlines, budgets and intended uses.