Physna3D data management system with an innovative geometric AI search function

- Home /

- Service / Solution /

- Physna

Fast and accurate shape search and user-friendly analysis functions based on our unique AI algorithm extracts value out of 3D data and significantly streamlines operations

Common challenges

-

Data searches take time

Individuals own development data and data searches take time and effort

-

Data organization and management take time and money

There is an immense amount of data and introducing a system becomes a cross-departmental undertaking that crowds out development tasks

-

Past data is not being reused or standardized

Data is not being used effectively; similar products are being manufactured and duplicate materials are being procured in design, procurement, purchasing, and manufacturing

What is Physna?

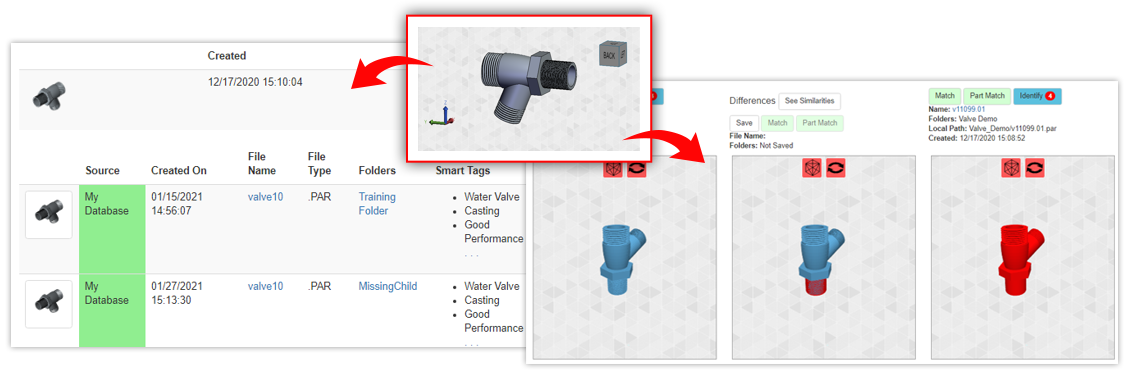

Physna is a new 3D data management solution that enables multi-dimensional search with 3D shapes as the key.

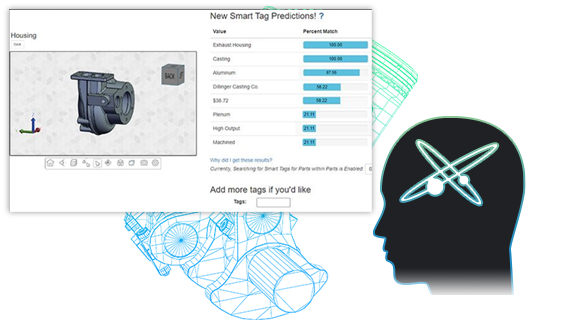

Physna, which leverages a unique algorithm and sophisticated deep learning technology, codifies all kinds of 3D data and uses 3D data to process and analyze the internal structures of parts and assemblies to accurately search and analyze the 3D model in question. It also allows for easy 3D data searches by non-CAD users with just the name of the part through tagged metadata and AI training on 3D data. The 3D data structures built in the cloud can be used regardless of the CAD system such as PLM or PDM which allows for easy access to past manufacturing data that may be lying dormant.

This promotes the use of 3D data in a wide range of work from design, production, purchasing, and procurement, to maintenance and could lead to dramatic increases in efficiency.

-

Powerful 3D search

- Fast and accurate 3D model search

- Searching shapes within complex compound parts

- Optimization of management using metadata

-

Can be adopted flexibly

- Operability that allows for use by non-CAD users

- No need for data conversion at adoption

- Does not require large-scale system development

-

Highly accessible

- Can handle all 3D data formats

- Can link with PLM and other systems

- Accessible from mobile devices

SOLIZE compiles useful data that is lying dormant within the company to promote the efficient use of 3D data.

Physna’s characteristics

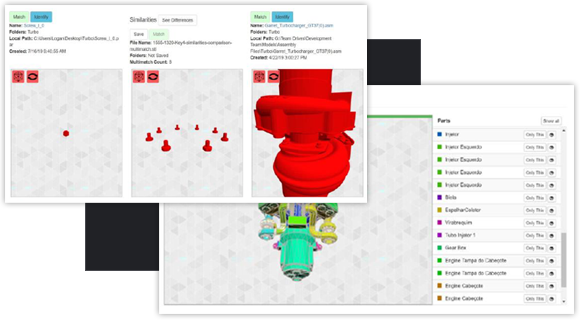

Powerful 3D search and shape comparison

Instantaneously search and compare similar 3D data from a massive database using the 3D data shape as the key

-

Data analysis capability that continues to grow

A unique AI learns from trends and increases data search accuracy

-

Search for parts within an assembly

Search for layouts of each component part, substitutes, and similar data

-

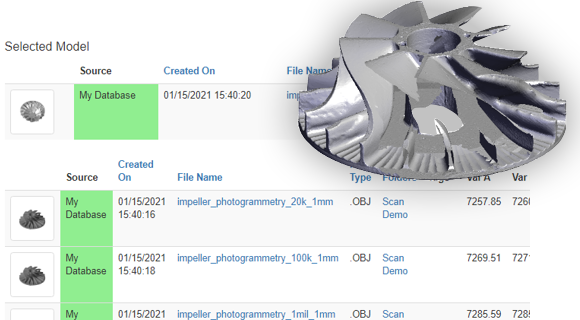

Search using scanned data

Shape searches are possible even if the scanned data is missing shapes

-

Supports any file format

Can analyze and search using almost all available 3D file formats

-

Can be used in all kinds of scenarios

Data can be promptly uploaded without a server

-

Advanced security capabilities

All data is encrypted and managed

Use cases

- Purchasing and procurement personnel can optimize parts management costs

-

- User

- Purchasing and procurement personnel, parts manager

- Challenge

- Identical parts are not being distinguished and are repeatedly purchased and procured while continuing to be managed under different part numbers and names.

- Expected improvement

-

・Eliminate duplicate purchasing and procurement processes, and advance negotiations with the best supplier

・Reduce management costs by managing the stock of the same part in smaller quantities to reduce storage space

Before the adoption of Physna

The same part is procured from different suppliers

After the adoption of Physna

Supplier selection is optimized

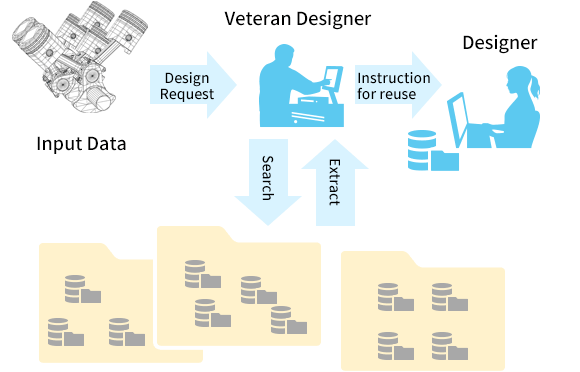

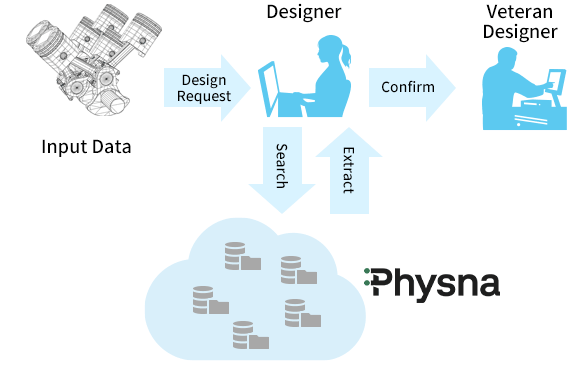

- Search for design data that can be repurposed from input 3D data

-

- User

- Designer (initial concept development to detailed design)

- Challenge

- Searching for data similar to the input data requires contacting a designer who was involved in that project

- Expected improvement

- Files from similar projects can be identified and repurposed just from the shape of the input data without having to contact the designer at the time (experienced personnel)

Before the adoption of Physna

Useful data cannot be found without contacting an experienced designer

After the adoption of Physna

Inexperienced designers can search for similar data

Designers can focus engineering work - Identify the appropriate maintenance part on site in a timely manner

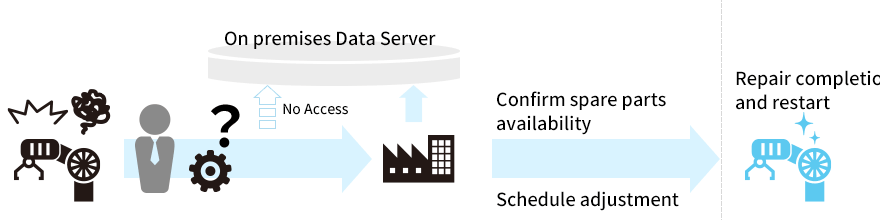

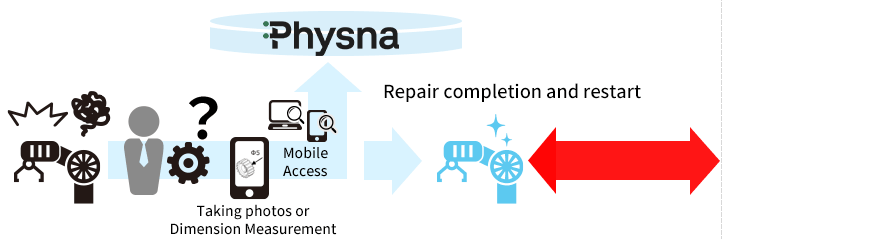

-

- User

- Manufacturing line support division

- Challenge

- Identifying parts during equipment maintenance on site takes time and impedes timely response

- Expected improvement

- Scan parts and search based on their shaped to swiftly identify and procure maintenance parts, reducing downtime

Before the adoption of Physna

Part information cannot be queried at the site, and response takes time

After the adoption of Phynsa

Parts are scanned and the maintenance part is searched from the photo or name, allowing for swift recovery

- Have consumer sales representatives recommend the appropriate product

-

- User

- Sales representative that handles many types of products such as building materials, metal molds, machined parts

- Challenge

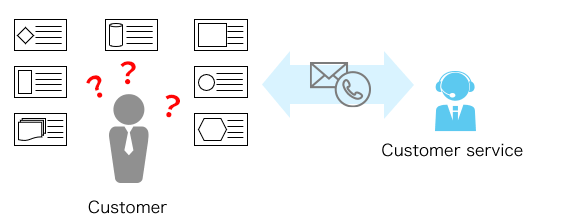

- When customers visit the stores, they see many products that are similar to what they want. Identifying the exact item that they are looking for requires in-depth discussion and time

- Expected improvement

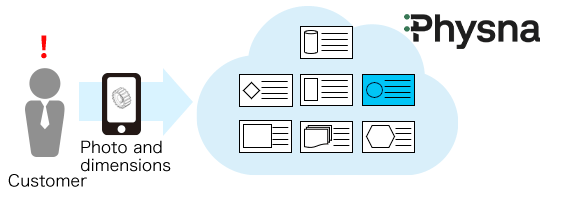

- Can propose candidate products based on product scan information (e.g., photos, dimensions) from customers

Before the adoption of Physna

Missed out on turning people who couldn’t find the products they wanted into customers

After the adoption of Physna

Able to suggest products based on product scan information (e.g., photos and dimensions)

Introduction video

-

Physna technology overview

Assist engineering teams and product design teams

-

Why Physna can search for parts

The world available with Physna’s powerful geometric search

-

What is Physna’s PNA (Physical DNA)?

Unique algorithm and sophisticated 3D deep learning technology

![]()

About Physna, Inc.

An industry leader in geometric deep learning technology, Physna, Inc.’s software bridges the gap between the physical world and digital code by codifying the 3D world based on a deep understanding of the physical traits of objects in the real world and its relationships. Physna, Inc. is building the future of 3D software. By providing powerful search functions to the hands of innovators and creators, it has already improved engineering, industrial design and procurement. Its name is derived from “Physical DNA” which represents geometric traits which is the core of its technology.

In July 2021, it raised $56 million in a funding round led by Tiger Global with the participation of GV (formerly Google Ventures) and Sequoia Capital, bringing the company’s total funding to $86 million.

- (Note) Physna can handle most major 3D data formats including CATIA, NX, Creo, Solid Works, AutoCAD, Inventor, STEP, IGES, STL, and Parasolid. Please contact us for more details.