3D printing the final product

- Home /

- Service / Solution /

- 3D printing the final product

Providing comprehensive support from selection of parts that can be 3D printed to production

Due to the diversification of customer needs, there is an increasing demand for mass customization in order to differentiate from other companies. There is a growing demand for high-mix small-lot production in various fields, including automotive parts, industrial equipment, medical devices, and consumer goods. 3D printers have the advantage of being able to respond flexibly to these needs.

SOLIZE supports the selection of parts that can be 3D printed, material evaluation, redesign, production preparation, final product manufacturing, and expansion of parts that can be 3D printed by utilizing the knowhow of 3D printing that we have developed since our establishment in 1990, and the latest HP Jet Fusion 3D printer technology.

SOLIZE’s characteristics

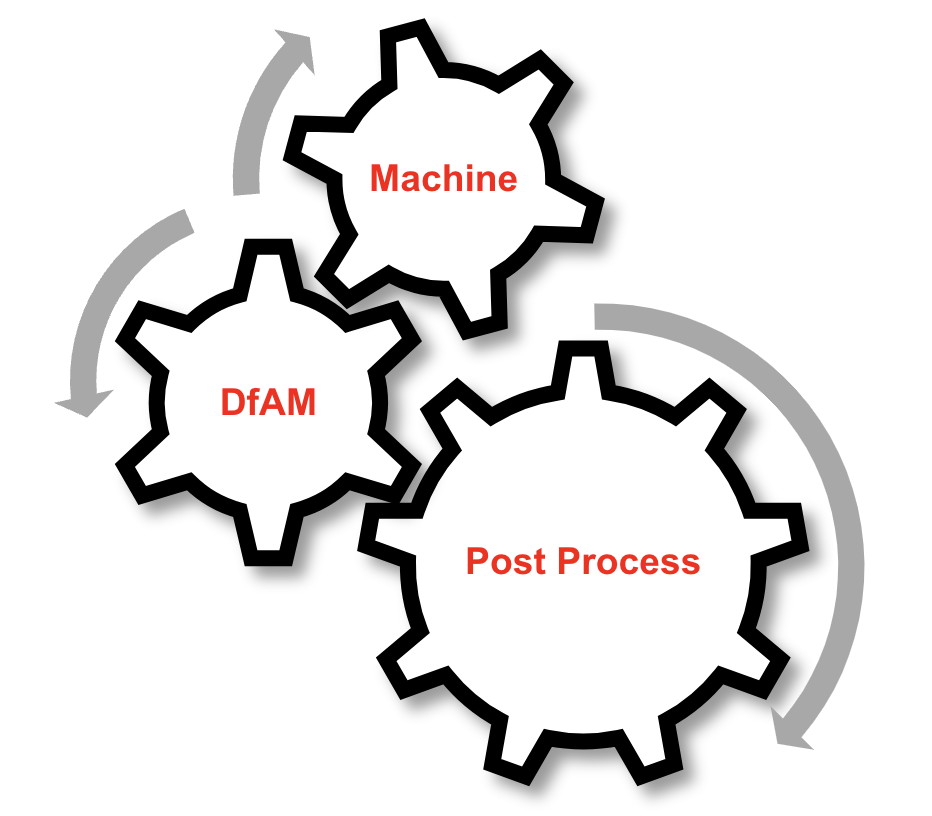

SOLIZE is well-versed in three important technologies in producing final products using a 3D printer.

Machine

- Production technology to prevent the machine from stopping, including maintenance

- Parameters and technology to produce stable properties

- Processes and material management technology

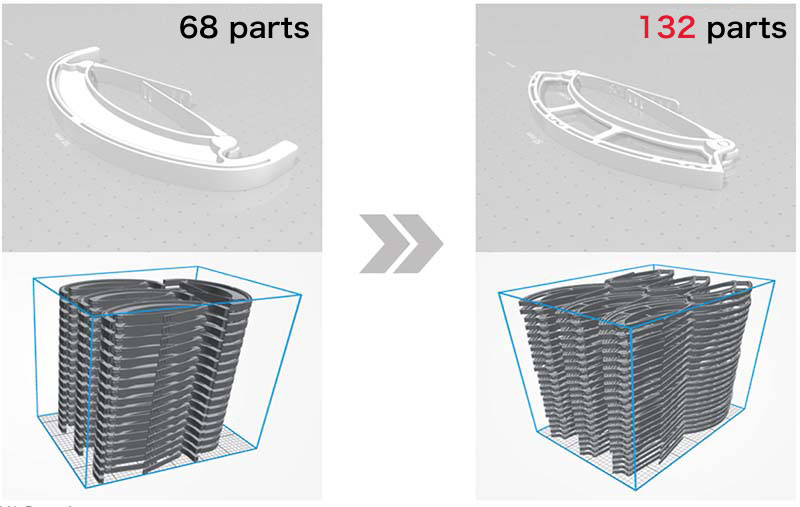

DfAM

- Value adding design

- Cost reducing design based on an understanding of the cost structure tailored to 3DP

- Decorative design considering customizability and design

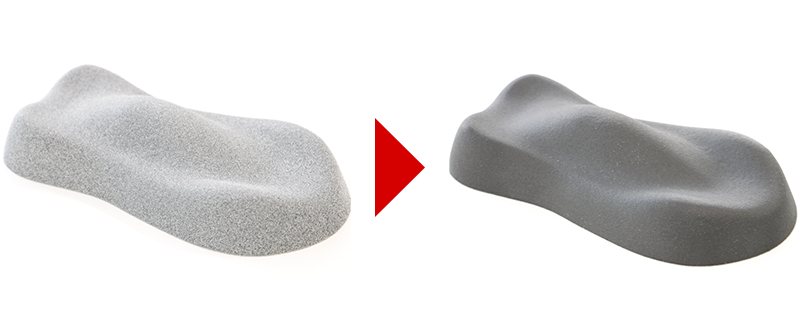

Post Process

- Automation of post-processing to reduce manufacturing costs

- Surface treatment technology to improve design

- Paint technology for 3DP

Recognized as the only HP Digital Manufacturing Network partner in Japan

In recognition for our 3D printing technology and quality management system fostered in the 30 years since our founding, we were certified as the only HP Digital Manufacturing Network in Japan. HP Digital Manufacturing Network partners are evaluated and certified based on their superior end-to-end 3D printing capabilities and production and quality management processes.

Use of 3D printers in manufacturing spare parts

- Digital stockpiling of spare parts for old models and spare parts made in small lots -

The production of spare parts using 3D printer is becoming increasingly common, both in Japan and overseas. The purpose of using 3D printers depends on whether a mold exists.

- When there is no mold: Heritage (Manufacturing of spare parts for old models)

- When a mold exists: Turn into digital inventory (can dispose of molds that will not be mass produced)

In either case, technical verification needs to be performed as to whether part requirements are being met.

SOLIZE can provide support for the whole process, from manufacturing to the selection of replacement parts, to feedback on design requirements, and post-processing.

SOLIZE’s equipment

-

HP Jet Fusion 3D 4200 series

-

HP Jet Fusion 5200 series

Applicable materials

In addition to the PA12, PA12GB (glass beads), and other materials we currently offer, we plan to offer a wide range of thermoplastic materials, including PA11, flame retardant materials, and elastomers. We create high-performance materials with low anisotropy that can also be used in production.

|

|

|

| PA11 Good snap fit property |

PA12 High in toughness |

PA12GB Glass-reinforced high-toughness material |

| Name of the material | Characteristic |

|---|---|

| PA11 | High in ductility. Capable of producing high-quality parts with flexibility. |

| PA12 | Capable of producing durable, low-cost, high-quality parts |

| PA12GB | Capable of producing rigid high-quality parts at low cost |