Simulation

- Home /

- Service / Solution /

- Simulation

Connecting customers with digital engineering

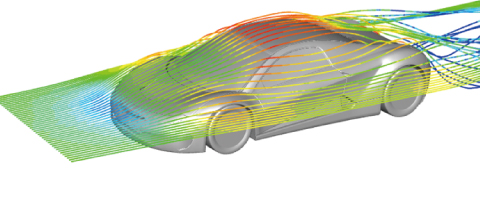

Assisting customers with next-generation CAE technology

SOLIZE performs various types of analysis from structural analysis, multi-body system analysis, computational fluid dynamics analysis, and electromagnetic field analysis to achieve an optimal design that keeps costs down while increasing performance and shortening development time. We can also propose boundary conditions if there are none based on test results.

As a pioneer in digital engineering, SOLIZE not only leverages CAE technology but combines it with SOLIZE’s manufacturing technologies to assist customers in solving problems and creating new value in developing the next generation of products development using CAE.

Characteristics of CAE engineering services

-

Can handle almost all areas of CAE related to the development of automobile vehicles

We have approximately 300 CAE engineers with expertise in structural analysis, multi-body system analysis, computational fluid dynamics analysis, and electromagnetic field analysis in Japan and abroad. We solve our customers’ problems and create new value through our engineering services, temporary staffing service, outsourcing service, and technical consulting service.

-

Assist in development by combining the benefits of onsite, offsite, and offshore services

We maximize our customers’ quality, cost, and delivery (QCD) benefits according to customer needs by combining resources in three locations: onsite (on the customer’s premises), offsite (at our company’s premises), and offshore (our company’s overseas sites). We offer a global engineering service that combines overseas resources and sites in addition to domestic ones.

-

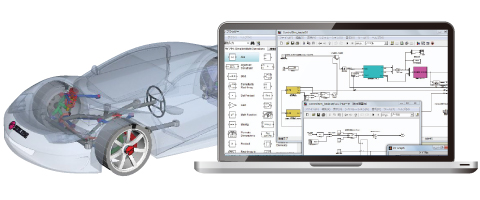

Realize systems engineering that links 1D analysis and 3D analysis

We also offer systems engineering that links 1D analysis and 3D analysis. In vehicle dynamics, we can simulate the vehicle system as a whole including the control model in partnership with SOLIZE’s MBD engineering service, in addition to a conventional evaluation of just the multi-body system analysis model.

-

Assist product design development using optimization analysis

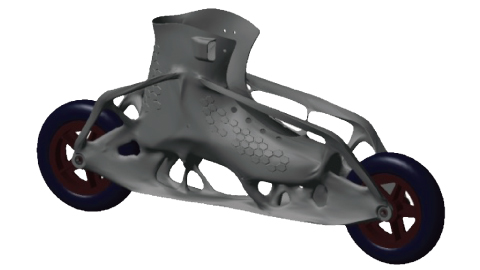

We assist in the pursuit of achieving high-performance requirements and additional value in new products through optimization analysis such as topology optimization. In partnership with SOLIZE’s 3D printing engineering service, we assist in product design development leveraging optimization analysis assuming small batch production via 3D printing.

-

Assist in design and development after CAE analysis

We can also assist in design and development after CAE analysis leveraging SOLIZE’s CAD engineering services, up to the realization of the product. We can quickly make prototypes for tests using 3D printing technology that can go through CAE analysis and contribute to shortening the development cycle.

Engineering service

Analysis engineering (structural, multi-body system, computational fluid dynamics, electromagnetic field)

We provide analysis engineering services such as structural analysis, multi-body system analysis, computational fluid dynamics analysis, and electromagnetic field analysis for automobile vehicle development. Experienced CAE engineers, mostly from the automatic OEM field, manage the project and assist in fundamental technology development using CAE, reducing lead time in product development, increasing design quality, and expanding calculation resources.

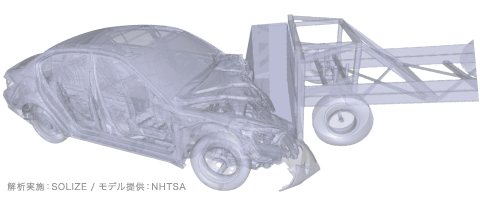

Large-scale CAE analysis and modeling commissioning

Our dedicated CAE analysis model engineers quickly and accurately create large-scale CAE analysis models for automobile collision and vibration analysis. We handle everything from coordinating the acquisition of CAD model data from each department to creating analysis models for individual parts to assembling the final full vehicle model. We have a track record of generating large-scale CAE analysis models for automobile OEMs, and have generated 40 to 50 vehicles every year over a period of more than 10 years.

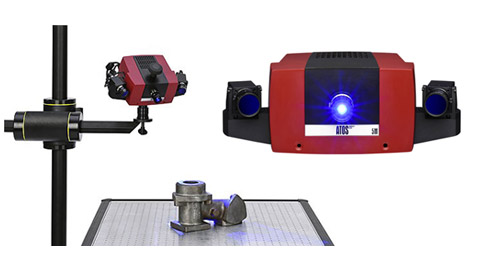

Reverse analysis from 3D scans

We create CAE analysis models from 3D scanned data of products and perform various CAE analyses. We can also accommodate requests to perform a CAE analysis for benchmarking and other purposes even if there is no 3D data. If the customer is performing the analysis, we can also provide CAE analysis model data with specifications that match the customer's analysis objectives, based on imported 3D scanned data.

CAE analysis, proposal, and production of testing models

We provide a one-stop service, from proposing methods for conducting CAE analysis to producing test models. We propose and produce models for use in tests in collaboration with our 3D CAD engineering service and 3D printing engineering service using 3D data that has undergone CAE analysis.

Technical consulting service

CAE development process improvement technology consulting

OEMs, suppliers, and CAE vendors will tackle the issues in the development process that use CAE analysis from the perspective of those working in CAE on the field and from a multifaceted perspective. By listening to, investigating, and analyzing the opinions of both the development team and management, we can bridge the gap between the two. We propose and implement solutions that optimize for the whole by providing a transparent development process and effective measures and avoiding falling into the trap of partial optimization.

Optimization analysis technology consulting

We propose useful optimized designs that integrate topology and shape optimization to meet multiple performance requirements while considering robustness and manufacturing constraints. We assist in developing product shapes that are unattainable with conventional methods using small-lot production via 3D printing and incorporating SOLIZE’s specific 3D printing manufacturing needs from the outset.

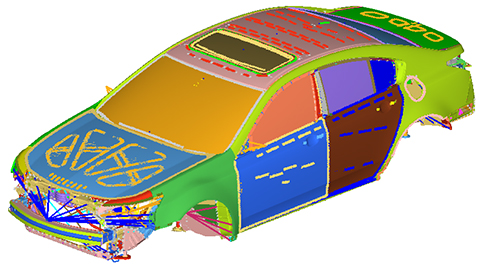

Full-vehicle multi-body system technology analysis

In line with the development process for automobile suspensions, we carry out full-vehicle model construction, performance evaluation calculations for the static and dynamic characteristics of individual suspension components, and driving simulations to evaluate the ride comfort and handling stability of the entire vehicle.

In addition to vehicle simulations using just multi-body system analysis models, we can also perform simulations of the entire vehicle system, including control models, in collaboration with SOLIZE's MBD engineering services.

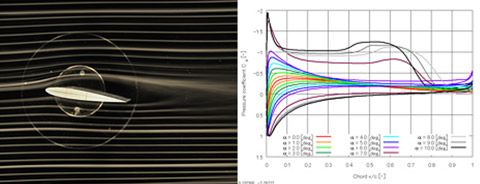

Computational fluid dynamics analysis technology consulting

Our team of top-class engineers, with over 20 years of experience in computational fluid dynamics analysis (CFD) at automobile OEMs and some with PhDs, will support customers in solving their most advanced challenges. We provide cost-effective technical consulting services through collaboration between Japan and India, where we have a local subsidiary that also employs many engineers with PhDs and master's degrees.

Project examples

-

Automobile-related

- NVH analysis of a body in white

- Behavior Assesment when going over bumps (Ride comfort assesment)

- Air conditioning airflow / temperature distribution assessment

- Engine coolant flow / temperature distribution assessment

- Creation of analysis mesh data

-

Aerospace

- Aircraft parts

Structural analysis / calculation of the safety factor for the maximally stressed area

- Aircraft parts

-

Electronics

- Smartphone

Drop analysis / redesign based on analysis results

- Smartphone

-

Medical devices

- Diagnosis equipment: Structural analysis

-

Other

- Cosmetics container: Structural analysis