Support for introducing 3D printing technology

- Home /

- Service / Solution /

- Support for introducing 3D printing technology

Supporting our customers’ efforts to strengthen their competitive edge by advancing their efforts to “master additive manufacturing” as a project

In recent years, with the development of 3D printer equipment, software, and modeling materials, advances have been made in additive manufacturing (AM) as a technology that can be used to produce final products. AM technology differs from existing manufacturing methods in many ways. There are many issues to overcome before AM can be incorporated into Japanese manufacturing processes, and the barrier to adoption is very high for many companies.

Common inquiries

- I want to use or deploy AM technology but don’t know where to start

- I don’t know what AM technology will do for the company

- I want to increase our competitiveness by developing products and production technologies using new technology

- I’m knowledgeable enough about 3D printers and don’t have the verification facilities. I want you to:

・Verify if optimum design to meet these functional requirements is possible

・Verify if this structural idea can be realized

・Verify if a product can be made using this kind of material

・Verify if this can be made with low environmental impact material

Even if customers understand the various benefits of AM technology, discussions may not progress if customers have little experience using and deploying AM technology.

SOLIZE’s service for supporting the introduction of AM technology promotes initiatives for the customer to master AM as a project.

SOLIZE assists customers in strengthening their competitive edge by combining our market research and advisory services, technical support service, and product development support service in response to our customers' business environment and issues.

Services

Support in the basic research field: Development of technologies underlying the use of AM

We support the development of technologies necessary to create a product using 3D printers.

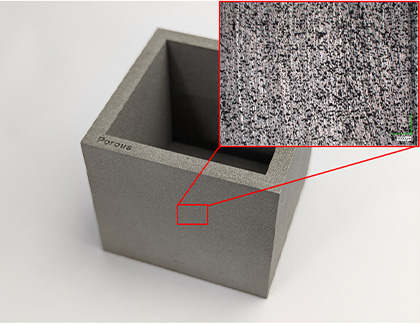

- Design of functional structures (topology, lattices, porous materials, metamaterials)

- Product performance prediction (structural analysis, thermal fluid analysis)

- Development of materials (special material evaluation as a commissioned project, recycling)

- Analysis of manufacturing processes (residual stress, deformation)

- Advancements in the manufacturing processes (realize thin-walled microstructures)

Product development support: Use of AM based on design and analysis

We work with customers from the design stage to develop technologies that combine 3D printing, design, and analysis to increase the added value of AM.

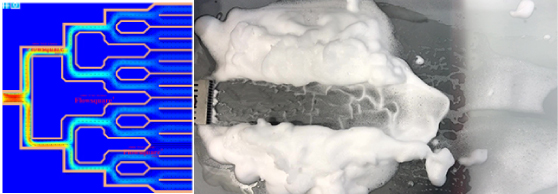

- Improve thermal/fluid control efficiency (thermal fluid analysis)

- Enhance functions (optimize structure, lattice, predict product life)

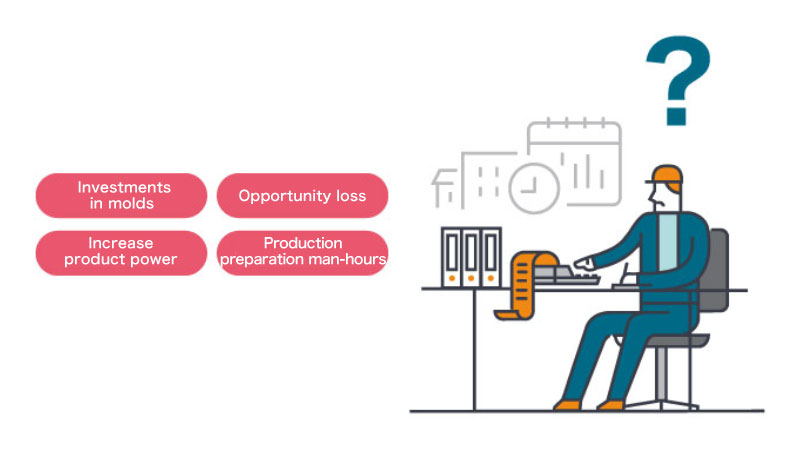

Product development/planning/test marketing support: Mold-less manufacturing service

Using SOLIZE’s technologies to “master AM,” we support customers from development to manufacturing of small batches without using metal molds.

Smart AM solutions

We provide a one-stop service from design and analysis to production, evaluation, and verification, and propose solutions that resolve issues and increase value in metal additive manufacturing.

SOLIZE’s characteristics

SOLIZE provides services in all areas, including “sales of devices”, “molding services”, and “developing functions”, and is able to make proposals that meet the needs of our customers.

| Characteristics | Approach | |

|---|---|---|

| Resource (Equipment and materials) |

|

|

| Capability (Response capability and development capability) |

|

|

| Competence (Track record and experience) |

|

|